Liquid Level Control

Situations:

- Electronic probes require calibration with the level column (standpipe) and are susceptible to damage or bending and signal drift.

- Sealed motorized control valves do not close upon power failure and they do not give a visual indication of valve position.

Solutions:

- Danfoss AKS 4100/4100U liquid level sensor introduces the proven technology TDR (Time Domain Refl ectometry) ensuring reliability and high accuracy is a very reliable choice. All sensors in the new AKS 4100/ 4100U family are easy to install and fully fl exible. No on-site calibration is needed, and the probe length can easily be adjusted on site.

- The Danfoss ICM motor valve equipped with ICAD actuator will close the valve upon power failure. The ICAD actuator also confi rms valve position and closure. Furthermore the special V-port design in the ICM regulating cone provides stable and smooth control characteristics compared to valves having a traditional fl at port design. It enables the temperature set-point to be adjusted to a higher level, which provides a higher suction pressure, and a much better COP, ultimately leading to signifi cant enegy savings.

Evaporator Control

Situations:

- A valve combination for a fl ooded evaporator operating on/off from a thermostat and with hot gas defrost is required. Pipe dimension is 25 mm, and there is a demand for butt weld DIN connections. It is a request to have 4 sideports for external connectors.

Solutions:

- For this application ICF 20-6-3, code number 027L3020 is recommended.

- On the same evaporator a hot gas valve to inject the gas into is needed. Pipe dimension is 32 mm, and there is a demand for butt weld DIN connections. It is a request to have 2 sideports for external connectors.

- For this application ICF 25-4-9, is recommended.

Solutions for ammonia refrigeration

The Safer Drain Valve

Situations:

- Liquid refrigerant can be trapped between the stop valve and drain valve causing an unsafe, high-pressure situation, or potentially damaging either valve.

Solutions:

- The internal relief device in the Danfoss QDV allows refrigerant to slowly bleed if internal valve pressure exceeds 260 psig. Further, the valve is easily actuated by hand (without tools), and has an internal spring mechanism to instantly close the valve if the actuator is let go. All QDV valves are in angle orientation with FPT outlet, suitable for safe draining.

V-Port for Chatter-Free Check Valve Operation

Situations:

- Check valve chattering at low load (fl ow) conditions.

Solutions:

- Danfoss CHV (check valves) and SCA (stop/check valves) provide an optimum solution to chattering with a V-port design. Active below 25% of opening to maintain adequate velocity at low capacities, the V-port eliminates chatter and noise. Available in angle and globe versions, the CHV and SCA are ideal for discharge lines in reciprocating and screw compressors including economizer

Check Valve Without Orientation Limitations

Situations:

- Pulsating lines, such as reciprocating compressor discharge lines, require a piston check valve that typically has orientation limitations.

Solutions:

- The compact, piston in-line NRVA check valve off ers the fl exibility for multiple orientations, maximizing ease of installation. Available in most common fl ange sizes up to 2½’’.

Sophisticated electronic controls

Liquid Level Sensors (AKS 4100/4100U)

- Available in cable or coaxial version

- Based on a proven techhology called Time Domain Refl ectometry (TDR) or Guided Micro Wave.

- Proven operation with all refrigerants in combination with oil.

- The cable version can easily be adapted to desired length.

- It is very compact and easy to handle, ship, install and use with different lengths and refrigerants

Motor Valves and Actuators (ICM and ICAD)

- The ICM motor valve and ICAD actuator assembly off ers a very compact unit with small dimensions.

- ICM valves with ICAD actuators are designed to regulate an expansion process in liquid lines with or without phase change or control pressure or temperature in dry and wet suction lines and hot gas lines.

- Temperature range: –60/+120°C (–76/+248°F).

- Max working pressure: 52 bar g (754 psi g)

Sophisticated electronic controls

Pressure Transmitters

- Temperature compensation

- Built-in voltage stability

- Suitable for harsh environments

- UL recognized for Class I, Group A, B, C, and D, Division 2

EKC 331 - Compressor or co

- EKC 315 - Evaporator controller (superheat)

- EKC 331 - Compressor or condenser capacit

- EKC 347 - Liquid lever controller

- EKC 361 - Media temperature controller

- EKC 366 - Interface module for PC/PLC media temp. control

- One platform – cost eff ective

- Easy to operate and very compact

- 4-20 mA input/output

- Third-party PC/PLC can modify setpoints

Electronic Expansion Valve(AKVA)

- Full velocity the valve combined with its damping orifice makes it ideal for flooded systems

- AKVA does not require manual adjustments for changes in AKVA capacity(10 to 100%)

- Temperature range: AKVA10-50/+60C AKVA 15+20-40/60C

- Max woking pressure:42bar

Reliable mechanical controls

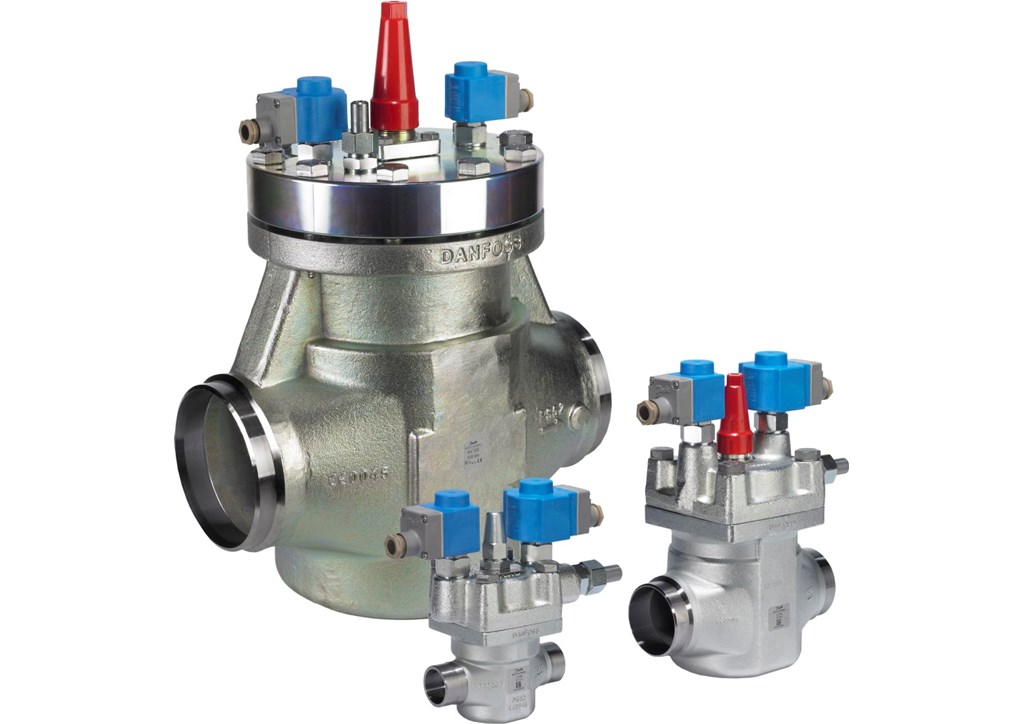

Valve station (ICF)

- The ICF valve station incorporates several functions in one housing, which can replace a series of conventional mechanical, electro-mechanical and electronically operated valves.

- The ICF valve station not only provides a number of advantages in the design phase of a refrigeration plant but also in the installation, service and maintenance.

- Temperature range: –60/+120°C (–76/+248°F)

- Max working pressure: 52 bar g (754 psig)

High pressure float valve (HFI)

- HFI is direct acting, sturdy and reliable high pressure float

- Can be mounted directly on vessels, PHE type condensers

- The float valve is equipped with a purge valve

- Temperature range: –50/+80°C (–58/+176°F)

- Max working pressure: 25 bar g (363 psi g

Modulating liquid level regulators, direct-controlled(SV1 & 3)

- Can be used separately as a modulating liquid level regulator. However, in ost cases, the SV is used as a float pilot valve for the main expansion valve type PMFL or PMFH.

- Temperature of medium: -50C/+65C(-58F/+149F)

- Max working pressure: 28 bar g (406 psi g)

Float Switch(AKS 38)

- Reliable SPDT micro switch

- Transparent switch box cover for visual indication

- Switch box can be rotated to improve visibility

- Temperature range: -50C/+65C(-58F/+149F)

- Max working pressure: 28 bar g(406 psi g)

Reliable mechanical controls

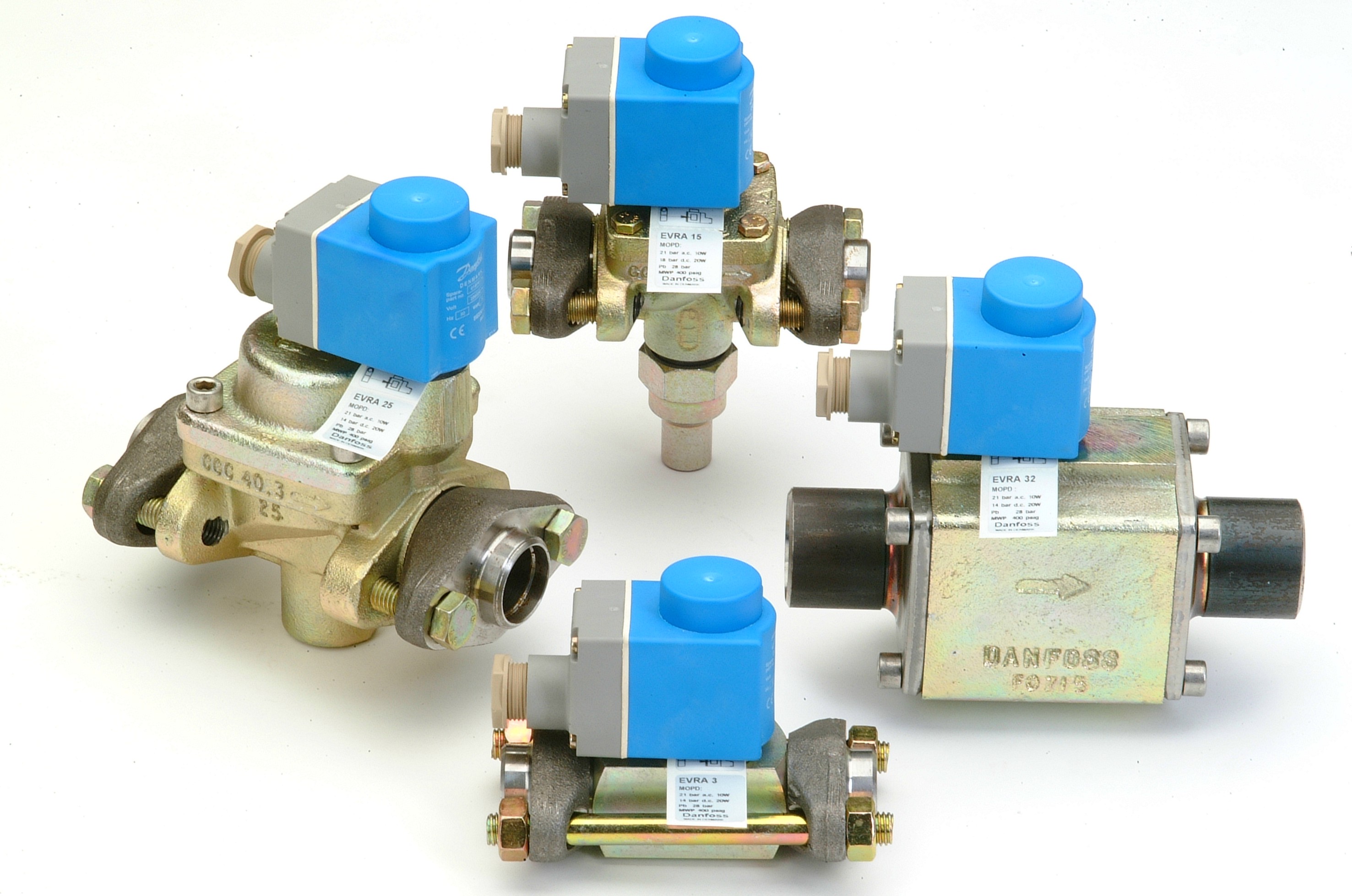

Solenoid Valv

- Danfoss solenoid valves can be installed in suction lines,return lines (liquid/vapour), pressure-equalizing lines, or bypass lines.

- Direct or servo-operated valves (EVRA)

- Servo-operated for assited lift(EVRAT)

- Direct operated, servo-operated, forced servo-operated with stainless steel bodies(EVRS/EVRST)

- Pilot operated(ICS/EVM)

- Gas powered two-stage opening solenoid valves angleway(GPLX)

- Gas powered two-stage opening solenoid valve straightway(ICLX)

Pressure Regulators (ICS Servo Valves)

- ICS servo valves are pilot operated valves for regulating pressure, temperature and ON/OFF function in refrigeration systems.

- Applicable for all common refrigerants including R717 and R744 (CO2) and non corrosive gases/liquids.

- Direct coupled connections

- V-port regulating cone ensures optimum regulating accuracy particularly at part load.

- Function module has a QPQ surface treated insert and a steel piston ring ensuring precise control accuracy.

- Temperature range: –60/+120°C (–76/+248°F).

- Max working pressure: 52 bar g (754 psig)

Pilot Valves

- Complete mechanical and electronic pilot valve program for precise pressure and temperature control:

- Constant-pressure pilot valve, CVP (LP) and CVP (HP)

- Diff erential-pressure pilot valve, CVPP (LP) and CVPP (HP)

- High pressure pilot valve, CVP (XP)

- Pressure-operated pilot valve with reference pressure connection, CVC

- Electronically operated pilot valve, CVQ

- Solenoid pilot valve, type EVM (NC)

- Solenoid pilot valve, type EVM (NO)

- Housing, type CVH for pilot valves,

Reliable mechanical controls

Extensive range of stainless steel components

- Stop valves, type SVA-SS. Sizes: DN 15 - 125 (½” - 5”)

- Regulating valves, type REG-SS. Sizes: DN 15 - 40 (½” - 1½”)

- Stop/check valves, type SCA-SS. Sizes: DN 15 - 40 (½” - 1½”)

- Check valves, type CHV-SS. Sizes: DN 15 - 40 (½” - 1½”)

- Filters, type FIA-SS. Sizes: DN 15 - 65 (½” - 2½”)

- Overfl ow valves, type OFV-SS. Sizes: DN 20 - 25 (¾” - 1”)

- Stop Needle valves, type SNV-SS. Size: G½

- Solenoid valves, type EVRS. Sizes: DN 3 - 20 (3/8” - 1”)

- Solenoid valves, type EVRST. Sizes: DN 10 - 20 (½” - 1”)

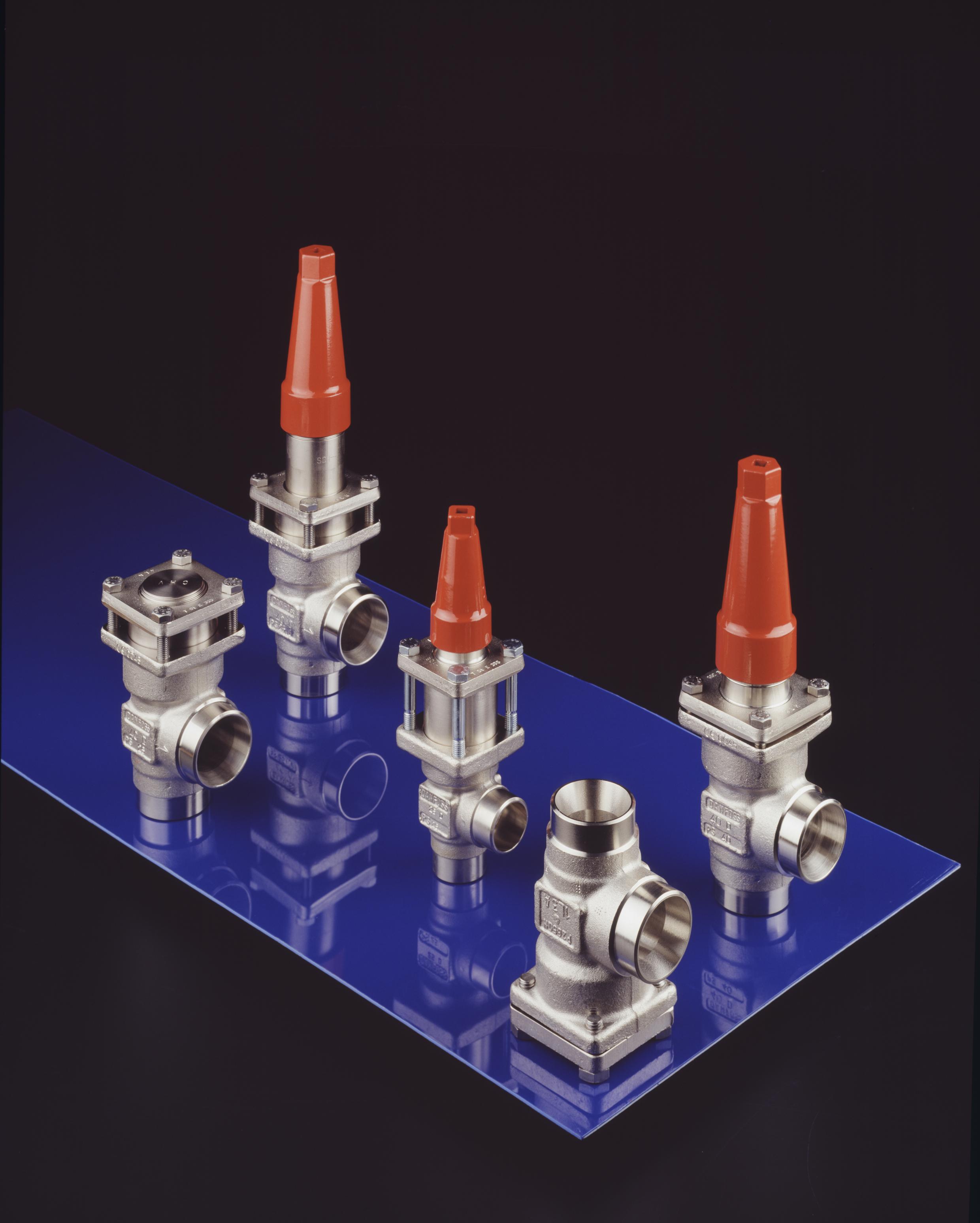

Stop Valves (SVA)

- SVA Stop Valves are available in angleway and straightway versions and with Standard neck (SVA-S) and Long neck (SVA-L) for insulated systems.

- Can accept fl ow in both directions.

- Temperature range: –50°C/+150°C (–58°F/+302°F Max working pressure: SVA-S/L (DN 15-65) 52 bar (754 psi) within the temperature range –50°C/+50°C (–58°F/+122°F)

Hand Expansion Valves (REG SA & SB)

- Part of the new SVL range

- Available in angleway and straightway versions

- Dual function-expansion/regulation and isolation

- Act as a normal stop valve in closed position

- Temperature range: -60/+150C(-76/+302F)

- Max working pressure: 52 bar g(754 psi g)

Strainer (FIA)

- Part o the new SVL range

- Available in angleway and straightway versions

- FIlter mesh is stainless stell mounted direct without extra gaskets means easy servicing.

- Twp types of filter inserts are available: Plain insert of stainless stell, pleated insert(DN 15-200)with extra-large surface

- Temperature range: -60/+150C (-76/+302F)

- Max working pressure: 52 bar g (754 psi g)

Check Valve (CHV-X) and Stop Check Valve (SCA-X)

- SCA-X/CHV-X stop/Check valves are designed to open at a very low differential pressure of 0.04 bar (0.58 psig)

- Laser cut V-ports provide excellent opening characteristics.

- Temperature range: -60C/+150(-76F/+302F)

- Max woking pressure: 52 bar g(754 psig)

Check Valves (In-line)

- Used in liquid, suction and hot gas line

- Damping piston for suitability in pulsating lines

- Temperature range: –50°C / +140°C (–58°F / +284°F)

- Max working pressure: 40 bar g (580 psig)

- Liquid lines only

- Direct couple to PM control valves

NRVA - piston-type with damping

NRVS - piston-type without damping

Quick CLosing Drain Valve(QDV)

- Handle can be positioned 360

- Can be supplied together with a stop valve for quick on site mounting

- Temperature range: -50/+150C(-58/+302F)

- Max working pressure: 40 bar g(580 psi g).

Overflow Valve(OFV)

- Combines the functions of an overflow valve, a check valve and a stop valve

- Can be closed manually and has backseating for service

- Temperature range: -50/+150C(-58/+302F)

- Max working pressure: 40 bar g(580 psi g).

Gauge, Purge and Needle Valves(SNV-ST)

- Compact and light valve for easy handling and installation

- No special flow direction required

- Temperature range: -60/+150C(-76/+302F)

Thermostatic & Electronic Expansion Valves

- TEA regulate the injection of refrigerant liquid into evaporators

- TEAT is used for refrigerant injection into the suction lin

- TEA nad TEAT have weld flange connections, exchangeable arifice and thermostatic element, and external pressure equalization.

Stop Valves(STC)

- STC Stop Vlaves are avalilable in angleway and straightway versions.

- Can accept flow in both directions.

- Temperature range: -50C/+150C(-58F/+302F)

- Max working pressure: 25 bar(365 psi)

Safety controls

Double Stop valves, DSV

- DSV are 3-waay valves designed specifically foe use with double safety valve systems.

- The valves are equipped with threads for nipple/flange conection for easy inspection or replacement of safety valves.

Safety Valves, SFA, SFV, BSV

- SFA / SFV models are back pressure dependent safety valves used for external relief.

- BSV 8 is back pressure independent safety relief valves forinternal release and pilot operations.

- Pressure range 10 to 40 bar for SFA / SFV and 10 to 25 bar for BSV.

- The operating pressure of the plant should be at least 15% below the set pressure (to allow perfect reseating after having been activated)

- Temperature range: -30/+100°C (-22/+212°F)

- TÜV pressure setting certificate for each valve is possible.